If you have built your own house, you know the problem of moisture in the building after interiors plastering. Construction dryers are distributed throughout the house to dry out the new construction. Dehumidifiers are also used after a burst pipe or a flood. For this period of time, homeowners are glad to have such devices available, but after that they are not needed for ages.

A classic case for a usage-based billing model. On a daily, hourly and even minutely basis, you are only charged when the device is actually in operation. The need for such billing models for critical as well as less critical assets is increasing. An hour meter is the solution. According to the retrofit principle, this is realised and retrofitted with the rapidM2M T32x without mechanical or electronic interventions in the device.

The T32x with the “Time Meter” IoT app is attached to the device. The easiest way to do this is with the magnetic holder that can be attached to all metal surfaces. Alternatively, the operating hours meter is attached to the device via a screw connection.

When it vibrates, it runs

But how can the T32x count the operating hours if it is only attached to the outside of the device? It has a 3-axis accelerometer. This detects that the device is running due to the movement or vibrations. For example, heat pumps, compressors, refrigeration dryers, motor-driven machines or vibrating units retrofitted with the hour meter.

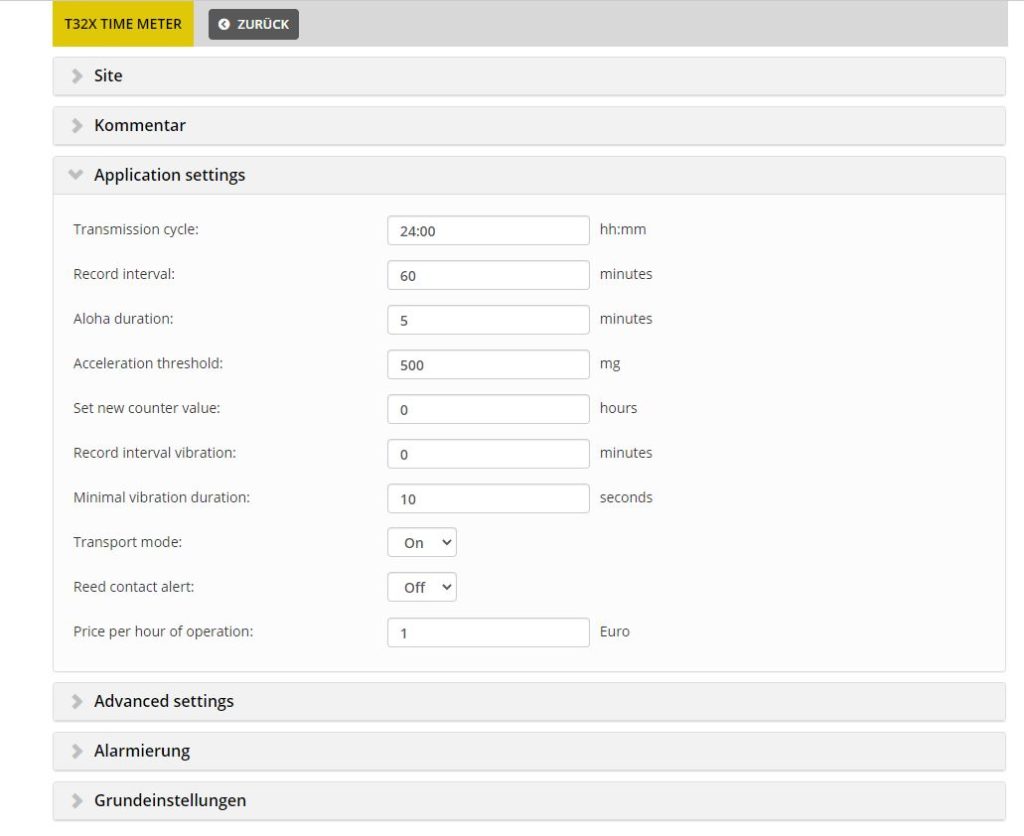

The vibration sensitivity, i.e. that value from which the device is considered “in operation” and the operating hours are counted, is configurable. By default, this is set to 500mg. In total, values up to 4000mg are recorded. In addition, the minimum vibration duration (default 10 seconds), from which the operating hours are counted, can be set.

During the transport of the device from one place of use to another, the vibrations must not be counted as operating hours. For this purpose, the T32x can be set to transport mode via the web platform.

An alarm can be triggered via the reed contact (only when mounted by means of a magnetic holder) if the operating hours counter is removed from the device. For this purpose, a corresponding alarm call plan must be stored on the platform.

Added value through configuration & evaluation platform

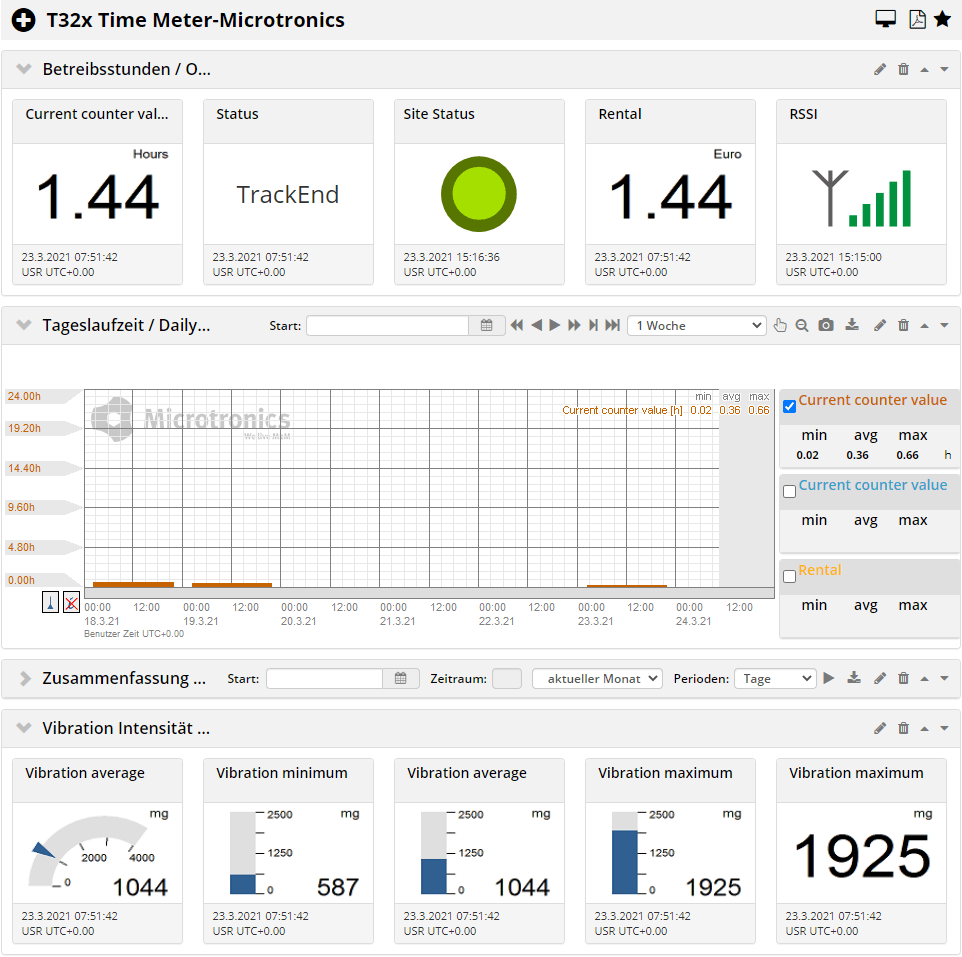

The biggest USP compared to similar hour meters is the fully integrated platform. On this, the data is collected and reflected in corresponding evaluations. The online platform, through which the device is also configured, completely replaces a local display.

With other hour meters, you often have to click through various values with a button to read the current readings. The values are then manually transferred to another system – often a list on a sheet of paper, which is then manually transferred to an Excel in the next step. Digitization is missing!

With the T32x and the integrated web platform, you can enjoy the benefits of digitization and reduce unnecessary additional efforts without media breaks. Via mobile communication, the operating hours and the position are regularly sent to the platform. The current as well as historical data are stored in the platform and can be accessed at any time.

The most important features at a glance:

- Recording of operating hours by vibration detection

- Evaluation of current and historical data via web platform

- Billing according to actual use

- Alarm in case of removal of the operating hours meter

- Positioning

- Analysis of data enables condition-based monitoring and predictive maintenance

Condition-based monitoring and predictive maintenance

In addition to usage-based billing, targeted revaluation of the data provides additional added value. Maintenance cycles can be optimised, and the functionality of the device is guaranteed.

Whereas devices used to be maintained in a time cycle of, let us say, one year, this can now be done much more effectively based on actual usage time.

Condition-Based Monitoring goes one step further. If the curve changes, i.e. the machine does not jolt or vibrate as usual, this allows maintenance requirements to be identified at an early stage. By monitoring the status beyond a mere “on” or “off”, there are further advantages. The change of the vibration curve is a sign that something is not running smoothly. Early measures reduce damage to the equipment and optimize service life and utilization.

Pro-tip: There are many other IoT apps available for the T32x, such as “Acceleration GPS Tracking” or “Access Technology Explorer”.